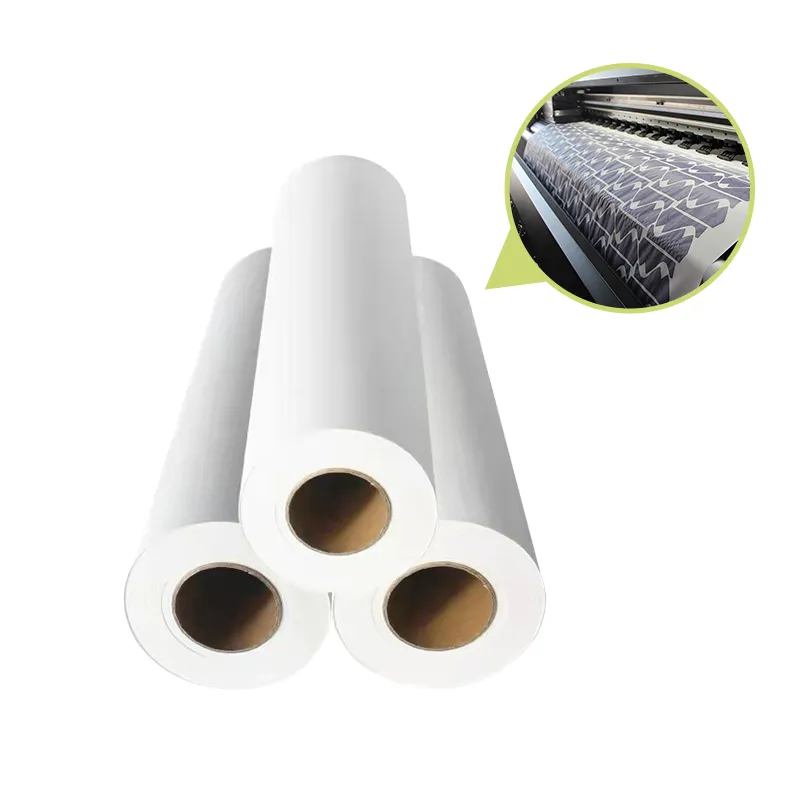

Sublimation Transfer Paper

Video

Features

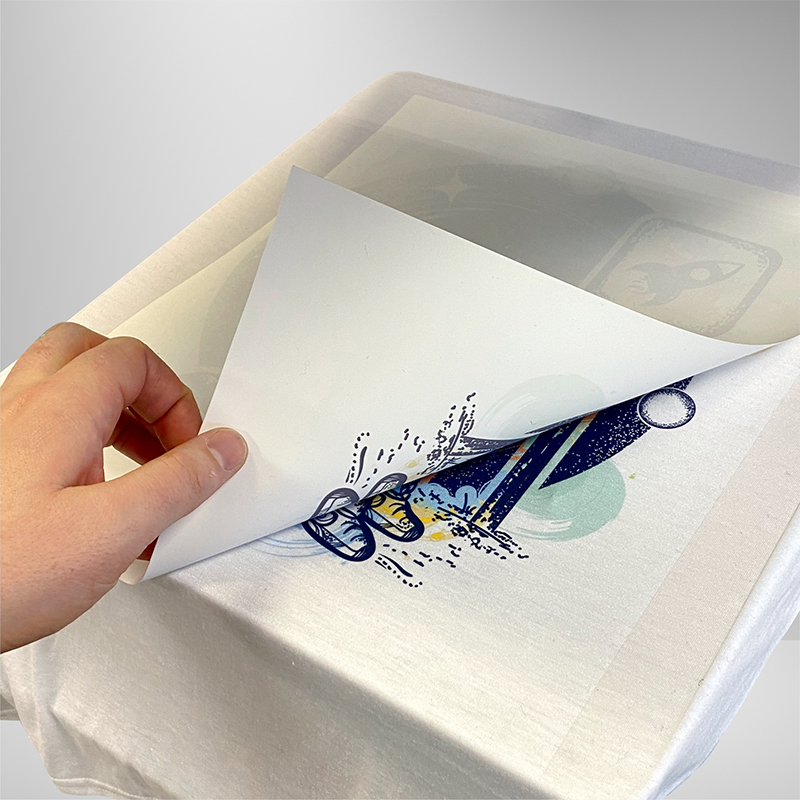

1. When print large area, the paper won't fold or curve;

2. Average coating, quickly absorbing ink, instant dry;

3. Not easy to be out of stock when printing;

4. Good color change rate, which is higher than other same products in market, the transfer rate can reach over 95%.

Parameters

| Product Name | Sublimation Paper |

| Weight | 41/46/55/63/83/95 G (see specific performance below) |

| Width | 600mm-2,600mm |

| Length | 100-500m |

| Recommended Ink | Water-based sublimation ink |

| 41g/ ㎡ | |

| Transfer rate | ★★ |

| Transfer performance | ★★★ |

| Max ink volume | ★★ |

| Drying speed | ★★★★ |

| Runnability | ★★★ |

| Track | ★★★★ |

| 46g/ ㎡ | |

| Transfer rate | ★★★ |

| Transfer performance | ★★★★ |

| Max ink volume | ★★★ |

| Drying speed | ★★★★ |

| Runnability | ★★★ |

| Track | ★★★★ |

| 55g/ ㎡ | |

| Transfer rate | ★★★★ |

| Transfer performance | ★★★★ |

| Max ink volume | ★★★★ |

| Drying speed | ★★★★ |

| Runnability | ★★★★ |

| Track | ★★★ |

| 63g/ ㎡ | |

| Transfer rate | ★★★★ |

| Transfer performance | ★★★★ |

| Max ink volume | ★★★★ |

| Drying speed | ★★★★ |

| Runnability | ★★★★ |

| Track | ★★★ |

| 83g/ ㎡ | |

| Transfer rate | ★★★★ |

| Transfer performance | ★★★★ |

| Max ink volume | ★★★★ |

| Drying speed | ★★★★ |

| Runnability | ★★★★★ |

| Track | ★★★★ |

| 95g/ ㎡ | |

| Transfer rate | ★★★★★ |

| Transfer performance | ★★★★★ |

| Max ink volume | ★★★★★ |

| Drying speed | ★★★★ |

| Runnability | ★★★★★ |

| Track | ★★★★ |

Storage Condition

● Storage life:one year;

● Perfect packing;

● Stored in an airtight environment with air humidity 40-50%;

● Before usage, it is recommended to keep it for one day in the printing environment.

Recommendations

● The product packaging has been well treated from moisture, but it is recommended to keep it in a dry place before used.

● Before the product is used, it needs to be opened in the printing room so that the product can reach a balance with the environment, and the environment is best controlled between 45% and 60% humidity. This ensures a good print transfer effect and finger touching the print surface should be avoided during the whole process.

● During printing process, the image must be protected from external damage before the ink is dry and fixed.